Here we are, the final post recapping our Ask Bill Anything webinar. Thanks for taking the journey with us. This week I’ll address the last question, which is also one that we get asked regularly over the years. Is it worth the investment to tag my equipment when we don’t have enough resources to do the Preventive Maintenance (PM) tasks in the first place?

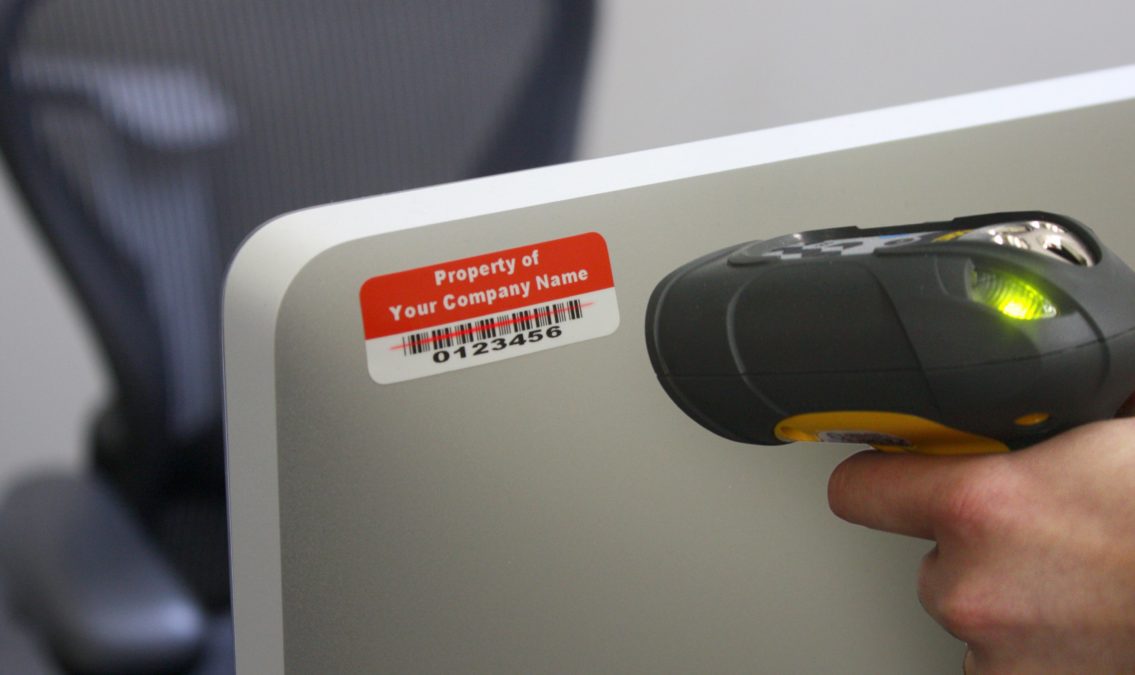

Asset tagging, the process of applying unique identifiers like barcodes or QR codes to equipment (while also gathering relevant information on specific pieces of equipment including make, model, serial number, etc.), requires both cost and effort. It requires boots on the ground, meticulous preparation, and data gathering. Additionally, once you are “done” with the initial tagging process, it requires the discipline to update the data as individual pieces of equipment are retired and new ones are added to your facilities. However, despite the initial and on-going investment, the benefits of asset tagging outweigh the expenses in the long run.

Asset tagging allows for granular tracking of individual equipment within work order systems. Instead of lumping maintenance costs under broad categories like “boilers” asset tagging enables precise allocation of activities and expenditures to specific pieces of equipment. This level of detail is crucial for informed decision-making, especially when it comes to capital planning. For instance, knowing the maintenance history and cumulative costs of maintaining a rooftop unit, or any piece of equipment over time can inform whether repairing or replacing it is more cost-effective.

Moreover, asset tagging simplifies equipment identification, reducing the margin for error and streamlining maintenance processes. In a facility with multiple similar units, relying on subjective identifiers like “the first one” or “the one in the middle” can lead to confusion and inefficiency. With asset tagging, each piece of equipment has a unique identifier, facilitating quick and accurate identification. This not only enhances operational efficiency but also minimizes downtime by ensuring maintenance tasks are directed to the right equipment promptly.

Technological advancements have further amplified the value of asset tagging. With QR codes and barcodes linked to comprehensive maintenance histories and work order systems, facility managers can access critical information with a simple scan using their smartphone or tablet. This seamless integration of technology not only improves data accuracy but also streamlines administrative tasks, allowing maintenance teams to focus more on proactive measures rather than paperwork.

So, while asset tagging may require upfront and on-going investments in time and resources, in my opinion, its long-term benefits justify the costs. From enabling precise cost allocation and informed decision-making to streamlining maintenance processes and leveraging technological advancements, asset tagging proves to be a valuable tool for maximizing equipment efficiency and prolonging asset lifespan.

For facilities striving to optimize their maintenance strategies, I would advise that investing in asset tagging is undoubtedly worth it. With this, we wrap up our Ask Bill Anything webinar questions series. Thanks for reading along and thanks again to all who attended and asked the questions during the webinar.